Applications of Sigma Mixer

- The sigma mixer is the best suited mixer for pasty, sticky, and gritty slurries with high viscosities. The following are some of the commonly used products that are mixed in the sigma mixer

- The sigma blade mixer is a commonly used mixer for high viscosity materials. This article details the construction of the sigma mixer, design and operational features, and its applications. The different variants of the sigma mixer design are discussed.

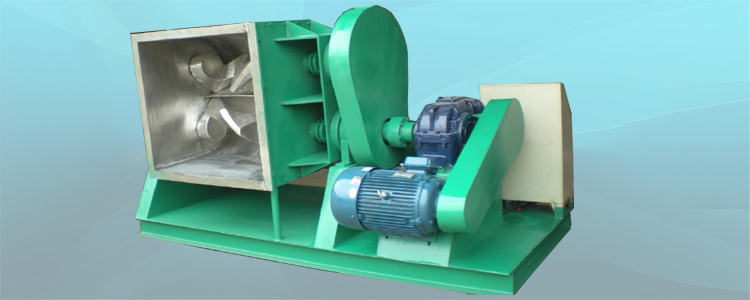

- The sigma mixer is one of the most popular used for mixing and kneading high viscosity materials. It belongs to the family of double arm kneader mixers.

- In mixers handling very viscous materials, it is necessary to promote both lateral and transverse motion of the material.

- The geometry and profile of the sigma blade is designed such that the viscous mass of material is pulled, sheared, compressed, kneaded, and folded by the action of the blades against the walls of the mixer trough.

- The extent to which this happens depends on the action of the blades - tangential or overlapping and the ratio of the speed of rotation of the blades.

- The helix angle of the blade can be modified depending on the required shearing